- HOME

- ABOUT

- PRODUCT

- EPS Machine

- EPS Foam Machine

- EPS Block Moulding Machine

- EPS Shape Moulding Machine

- EPS Batch Pre-expander Machine

- 3D Panel Machine

- Mgo Board Production Line

- Gypsum Board Making Machine

- Gypsum Board Production Line

- Fiber Cement Board Machine

- Fiber Cement Board Production Line

- NEWS

PRODUCT DESCRIPTION

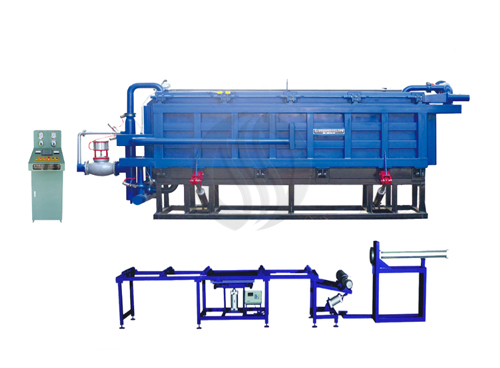

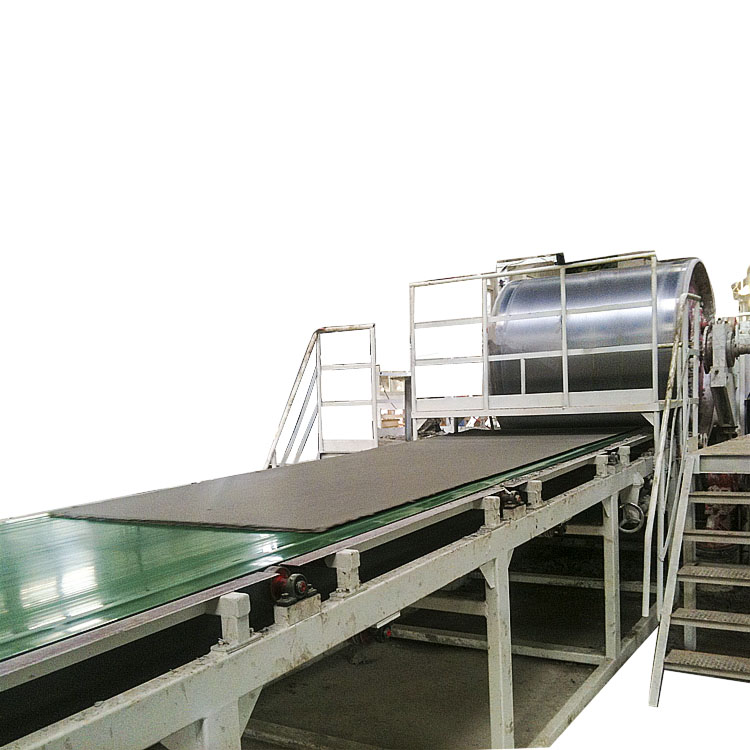

Automatic EPS shape molding machine can select different feeding processes such as regular feeding, inflating, and vacuum feeding, ensuring high feeding speed and uniformity inside the mould;With advanced hydraulic system, the main and auxiliary cylinders will respectively operate and lock the mould; with the differencial fast device, can improve the speed of moving mould journe.

Make eps foam beads to become big foam board through steam heating and wind cooling.With PLC English touch screen to realize full automatic production for feeding, heating,wind cooling, mould opening, mould closing and ejecting the foam box and different shapes.

●EPS shape molding machine adopts Japan Mitsubishi Corporation PLC, imported touch screen, full English display,graphical interfaces intelligent control, achieve man-machine conversation.

●The machine can carry out full automatic and semi-automatic.

●Taiwan AIRTCA hydraulic system is stable run, low noise, high clamping force.

●Vacuum system accelerates product shaping speed, shorts the cooling time, reduce product water content.

●Optimized design is clear and easy with high intensity and high performance-price rate.

●EPS machine can carry out heating, cooling, feeding and ingot stripping process to adapt todifferent EPS products.

●Perfect malfunction checkout system and motor protecting system which guarantees safe runningof equipment.

- 上一篇:EPS Block Molding Machine

- 下一篇:没有了

- PRODUCT